Friday, July 28, 2017 at Oshkosh's EAA's AirVenture, Rachel, my wife, and I entered the final year of our 42-year LongEZ building marathon. We discovered that each member of our vendor team was not only working on their latest and greatest designs, but was also working hand-in-hand with other team members. In the order of our visits last Friday:

1. SteinAir, Inc., www.SteinAir.com (panel maker & avionics distributor) – Mr. Stein Bruch, president, informed us that it was good that we waited a year for Dynon’s (EFIS), most recent product from pricing, hardware and software perspectives.

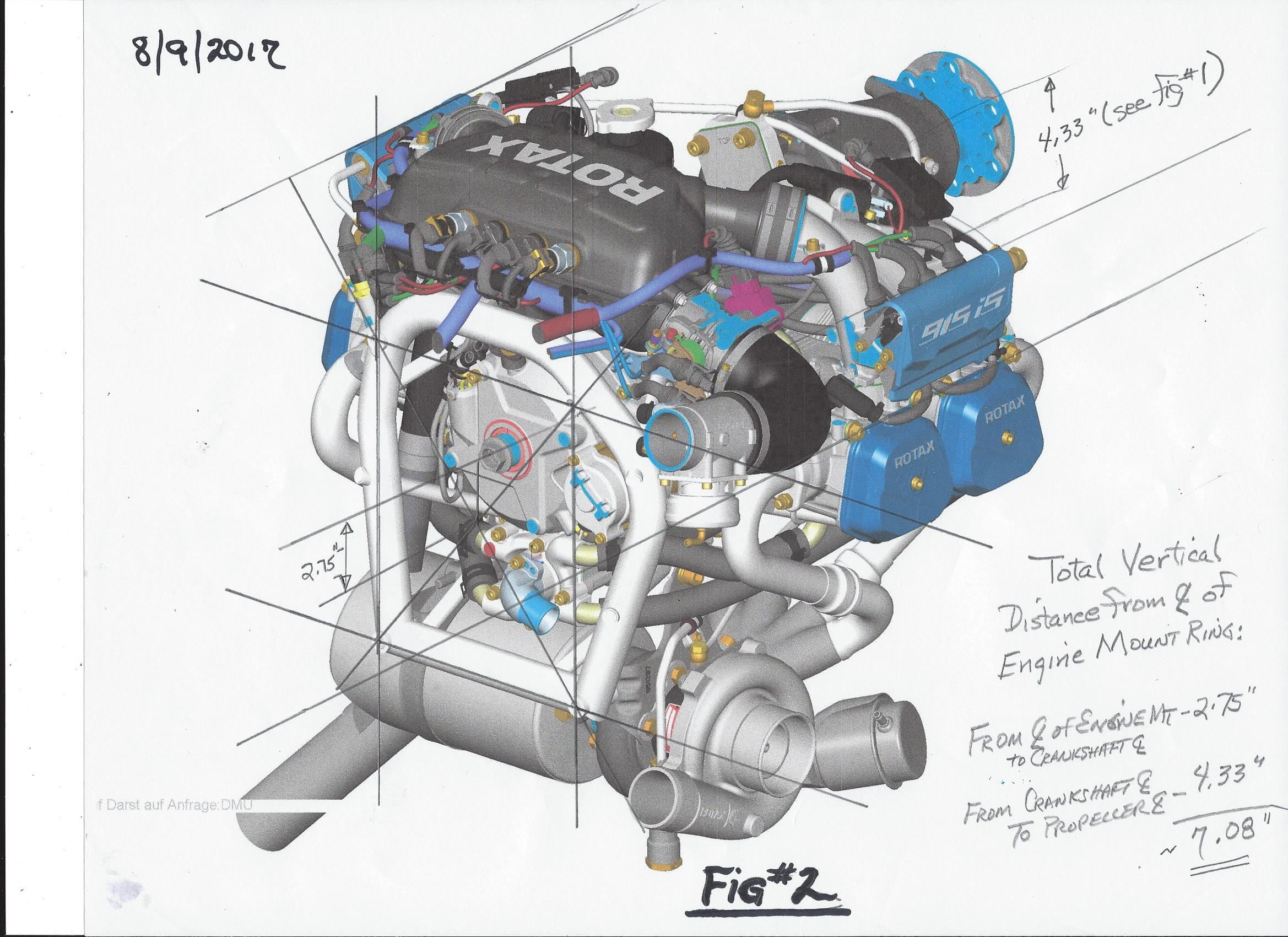

2. ROTAX Aircraft Engines – We learned about Stock System's computer-controlled, single controlled, pitch, mixture and RPM system; the cooling systems (water, oil & turbo-charger); the dual-ignition electrical system; the electronically controlled fuel injection system and real time engine Telemetry available to users, worldwide, via satellite. All the above to support ROTAX’s belief of placing SAFETY as job Number ONE !

3. MT-Propeller - MT is working closely with ROTAX, to develop an efficient 915is engine-variable pitch propeller system for ROTAX’s customers. Since I will have a BRS Parachute on board, I will also need two (2) [one front seat, one back seat] manually activated switches that will feather the propeller prior to chute deployment.

All the above to say that Rachel and I are very excited that our ‘never ending project’ is nearing completion with the latest and best that technology can offer. We are committed to fly by 7/24/2019.